BOOST CREEP

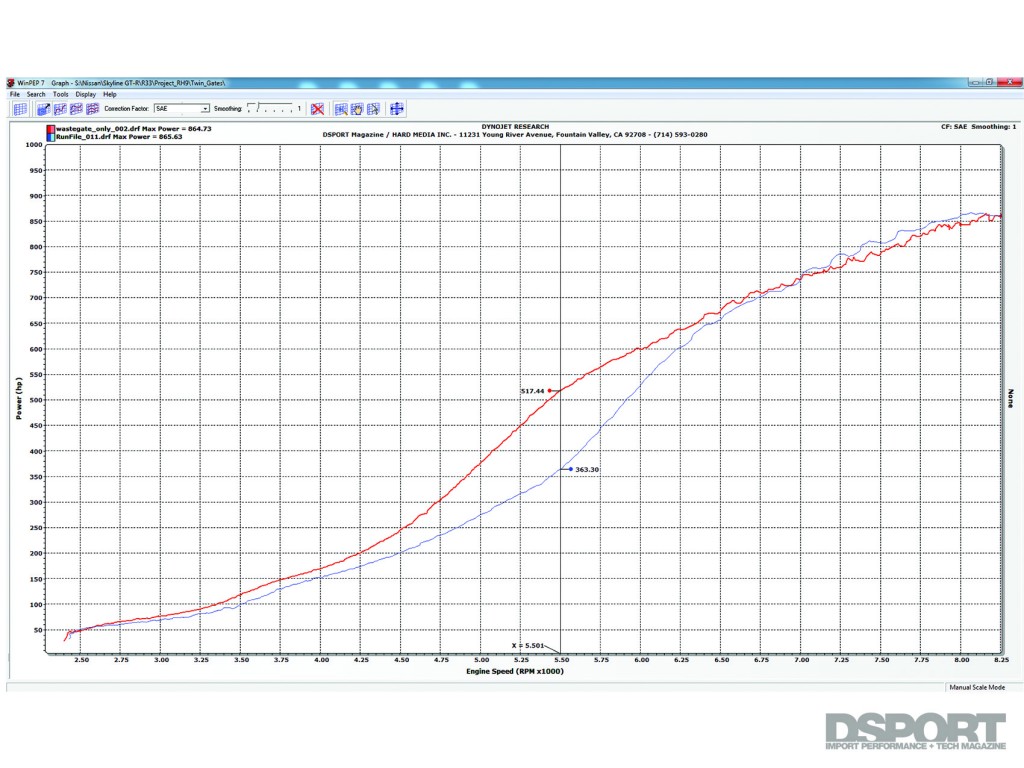

When a turbocharger system is set up with a wastegate that’s too small (meaning it can’t channel enough exhaust flow away from the turbine section), the result is boost creep. Boost creep is the term applied to the resulting boost pressure climb made at higher rpms by under-gated turbocharger systems. If a desired boost level is 20psi but boost pressure climbs from 20 to 25 psi near redline, this system would be described as showing 5psi of boost creep. The solution is a new wastegate that either lifts higher or has a bigger valve to channel more exhaust flow away from the turbine section.

When a turbocharger system is set up with a wastegate that’s too small (meaning it can’t channel enough exhaust flow away from the turbine section), the result is boost creep. Boost creep is the term applied to the resulting boost pressure climb made at higher rpms by under-gated turbocharger systems. If a desired boost level is 20psi but boost pressure climbs from 20 to 25 psi near redline, this system would be described as showing 5psi of boost creep. The solution is a new wastegate that either lifts higher or has a bigger valve to channel more exhaust flow away from the turbine section.

HOW MUCH WASTEGATE DO YOU NEED?

Whenever you improve the flow of exhaust gasses through the turbine section of the turbocharger, the dependence on wastegate flow diminishes. Increasing the size (A/R rating) of the turbine housing, size of the downpipe and the size of the turbine wheel all reduce the exhaust load that the wastegate will need to handle.

[pullquote]IF YOU HAVE ENOUGH WASTEGATE, DON’T FIX WHAT IS NOT BROKEN[/pullquote]Stepping up compressor flow with bigger compressor wheels and housings, as well as improving the volumetric efficiency and rpm potential of the engine will generally increase the flow demands on the wastegate.

The ultimate question of “how much wastegate do you need?” is very difficult to answer. A number of both static and dynamic factors will influence the answer. Our recommendation is simple. If you have enough wastegate (boost pressure doesn’t creep at high rpms past the desired level), don’t fix what is not broken. If you don’t have enough wastegate start looking at wastegates that will outflow your current wastegate.

SIZING UP THE RIGHT GATE

The right wastegate for your application must physically fit in your engine compartment and be able to function properly with the rest of your turbocharger system. In the accompanying Speed Shop, you’ll see some 1:1 scale images of some of the most popular external gates on the market. In addition, the gate must also use a flange that is compatible with your exhaust manifold. Today, the trend toward V-band flanges means that a wastegate can now be removed or installed much quicker. The V-band also allows for the wastegate to be rotated to the ideal position.

The right wastegate for your application must physically fit in your engine compartment and be able to function properly with the rest of your turbocharger system. In the accompanying Speed Shop, you’ll see some 1:1 scale images of some of the most popular external gates on the market. In addition, the gate must also use a flange that is compatible with your exhaust manifold. Today, the trend toward V-band flanges means that a wastegate can now be removed or installed much quicker. The V-band also allows for the wastegate to be rotated to the ideal position.

In addition to fitment, the proper wastegate must be able to channel enough exhaust flow to keep your boost pressures in check. Manufacturers design wastegates in a variety of valve diameters and physical sizes. If a number of similarly designed wastegates are offered from the same company with different valve sizes, the larger valve sized gates will be better suited for applications requiring additional wastegate flow. However, a 45mm wastegate from Company A won’t necessarily outflow a 38mm wastegate from Company B. How high the valve lifts off the seat and how well the valve housing flows are also important factors.

THE SPRING IS THE THING

Boost creep is one problem that can result from an undersized wastegate. However, even having the right gate can be a problem if the wastegate spring isn’t properly selected for the application. Select a spring that is rated at the minimum desired boost pressure. If you choose a spring stiffer than your desired low boost pressure level, you won’t be able to back down the boost pressure to your desired level. Remember, electronic and manual boost controllers only allow you to increase boost pressure over the wastegate’s spring-determined boost level.

Boost creep is one problem that can result from an undersized wastegate. However, even having the right gate can be a problem if the wastegate spring isn’t properly selected for the application. Select a spring that is rated at the minimum desired boost pressure. If you choose a spring stiffer than your desired low boost pressure level, you won’t be able to back down the boost pressure to your desired level. Remember, electronic and manual boost controllers only allow you to increase boost pressure over the wastegate’s spring-determined boost level.

If you choose a spring that is too light, exhaust backpressure may force the wastegate’s valve to open prematurely, partially spilling out exhaust flow before you reach your desired boost level. The result of too weak of a spring can be more evident on large-valve wastegates as opposed to small-valve wastegates. However, too weak a spring will be a problem for any wastegate. The result of too weak a spring is reduced boost response and performance. As we said before, the best spring is going to be the one engineered to deliver a boost pressure exactly at your minimum desired boost pressure.

If you choose a spring that is too light, exhaust backpressure may force the wastegate’s valve to open prematurely, partially spilling out exhaust flow before you reach your desired boost level. The result of too weak of a spring can be more evident on large-valve wastegates as opposed to small-valve wastegates. However, too weak a spring will be a problem for any wastegate. The result of too weak a spring is reduced boost response and performance. As we said before, the best spring is going to be the one engineered to deliver a boost pressure exactly at your minimum desired boost pressure.

KEEP IT CLOSED & CONTROLLED

One of the most counterintuitive (big word meaning “ass backwards” or exactly the opposite of what you thought) aspects of a wastegated turbo system centers on what happens to exhaust backpressure (pre-turbine) when the wastegate opens. It seems natural to assume that opening the wastegate would reduce the backpressure before the turbocharger. Instead, the preturbine backpressure increases once the wastegate opens. Hence, this is another reason why it is important to not choose a spring that is rated lower than your minimum desired boost pressure level.

THE BOTTOM LINE

The wastegate you select has to fit in your engine compartment, deliver the flow capacity that you need, set a safe minimum boost pressure and finally fit in your budget. Hopefully, this edition of Speed Shop will point you in the right direction to find the proper external wastegate for your application.